MIL-DTL-19834C

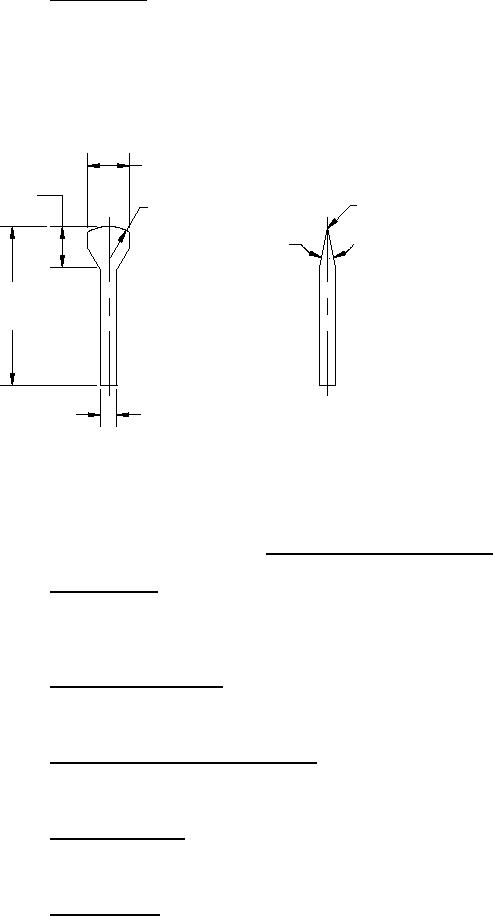

4.6.4 Edge adhesion. The edge adhesion shall be determined by repeatedly sliding a standard knife blade

along the surface to which the identification plate has been applied until it contacts the specimen edge and rides up

onto the surface of the identification plate. The knife blade shall be as specified for the Graham-Linton hardness

tester or equivalent (see figure 2). The knife shall be held with its handle inclined at an angle of 40 degrees to the

specimen surface and with the tangent to the midpoint of the cutting edge, parallel to the specimen edge. A 1 pound

effective load shall be applied to the knife in a direction normal to the identification plate surface. This test shall be

performed at each of the corners and at least one point on each side of the identification plate (see 3.5.3).

.312

±.031

.312

R .003 MAX

±.031

R .300 ±.031

INCHES

MM

30° ±1°

.003

.08

.031

.79

1.188

.125

3.18

±.031

.30

7.62

.312

7.92

1.188

30.18

.125 ±.031

NOTES:

1. Dimensions are in inches.

2. Metric equivalents (to the nearest .01 mm) are given for information only and are based upon 1 inch = 25.4

mm.

FIGURE 2. Knife blade for edge adhesion test.

4.6.5 Cyclic exposure. Identification plates shall be exposed to eight cycles of the following conditions:

16 hours at 105ºC, 6 hours in 20 percent salt (NaCl) spray at room temperature and 2 hours at - 40ºC. The edge

adhesion test (see 4.6.4) shall be conducted at the end of the 8th cycle on all identification plates except those

applied to Phenolic material.

4.6.6 Accelerated oxygen aging. Identification plates mounted on glass only, shall be subjected to 96 hours

oxygen bomb-aging at 300 pounds per square inch (psi) and 70ºC as outlined in method 5852 of FED-STD-191 to

determine conformance with 3.5.5.

4.6.7 Accelerated light and weather resistance. Identification plates mounted on phenolic panels only shall

be exposed to light from the flaming carbon arc of an accelerated weathering unit for 200 hours and intermittently

sprayed with tap water as outlined in method 5804 of FED-STD-191 to determine conformance with 3.5.6.

4.6.8 Salt spray resistance. Identification plates mounted on phenolic panels only shall be exposed to a 20

percent (NaCl) spray at 95ºF for 200 hours as outlined in method 606.1 of FED-STD-141 to determine conformance

with 3.5.7.

4.6.9 Water resistance. Identification plates applied to painted and unpainted test panels, prepared as

specified in 4.5, shall be totally submerged in tap water for a period of 12 hours. The plates shall then be examined

for conformance with 3.5.8.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business